Engineering

European Engineering team with 40+ years’ experience

Benefit from our experienced engineering team with 40+ years from makes INNZ products and customer support cost effective yet fully competitive with Premium brands.

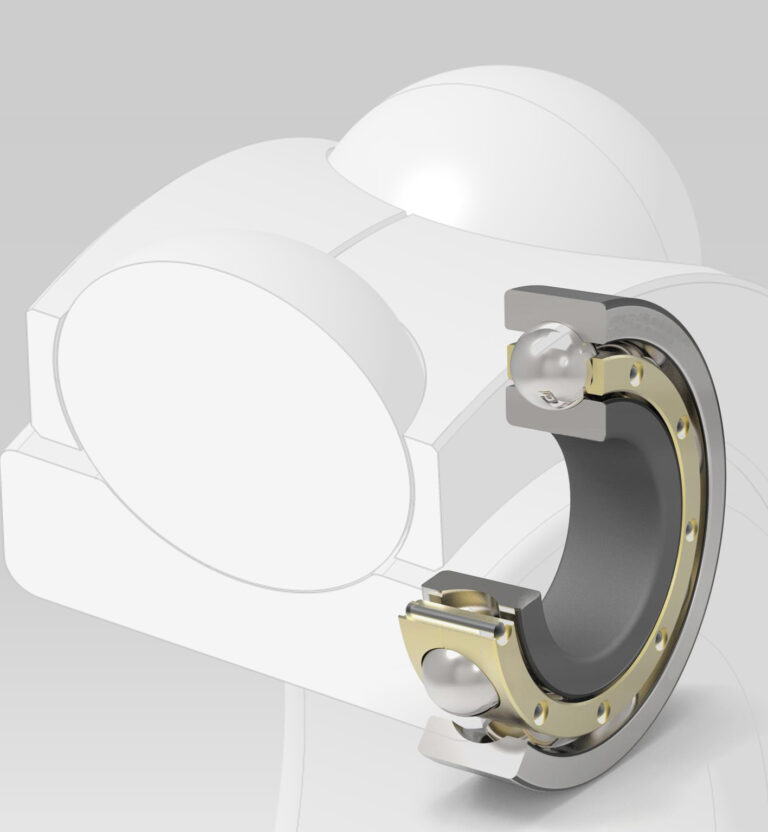

R&D and design and development of special bearings and special variants of standard bearings according to application requirement.

✓ optimized material selection including stainless steel and SV30(“CRONIDUR”)

✓ Optimized cage designs

✓ Special bearing features

✓ Development of test devices

✓ selecting materials and lubricants for optimum performance under given application conditions

Every process step is supported by our experienced bearing specialists right from RFQ’s, development, design, and manufacture, up to final quality inspection, field tests and mounting advice.

Free advice and application engineering support for our customers by our experienced engineering and customer service team.

Based on 40+ years’ experience, Europe team offers full support in bearing selection, design, and optimization of bearing positions.

✓ Bearing lifetime calculations

✓ Bearing fit selection

✓ optimization of clearance or preloading

✓ Lubricant selection and optimisation

✓ Optimisation of bearing internal design

✓ Support in designing bearing positions of tools and machines

Our European engineering team support in optimizing the performance of our bearings to outperform common products in terms of performance, service life and operating costs.

Based on a careful analysis of the actual requirements of a given application, our engineering team works out proposals for maximum cost efficiency of your application.

Our analysis yields economic benefits to our customers.

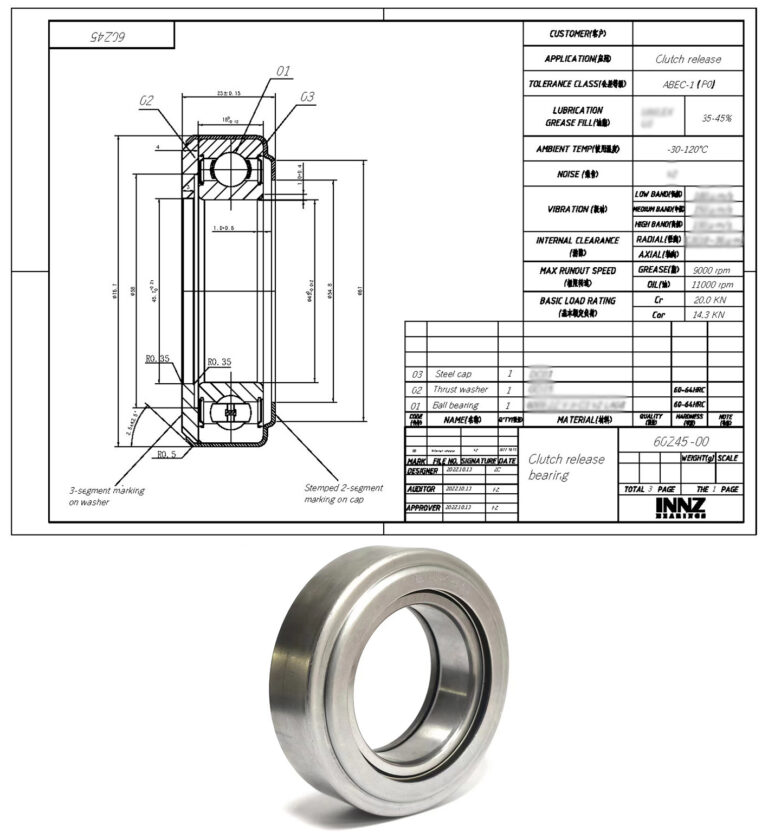

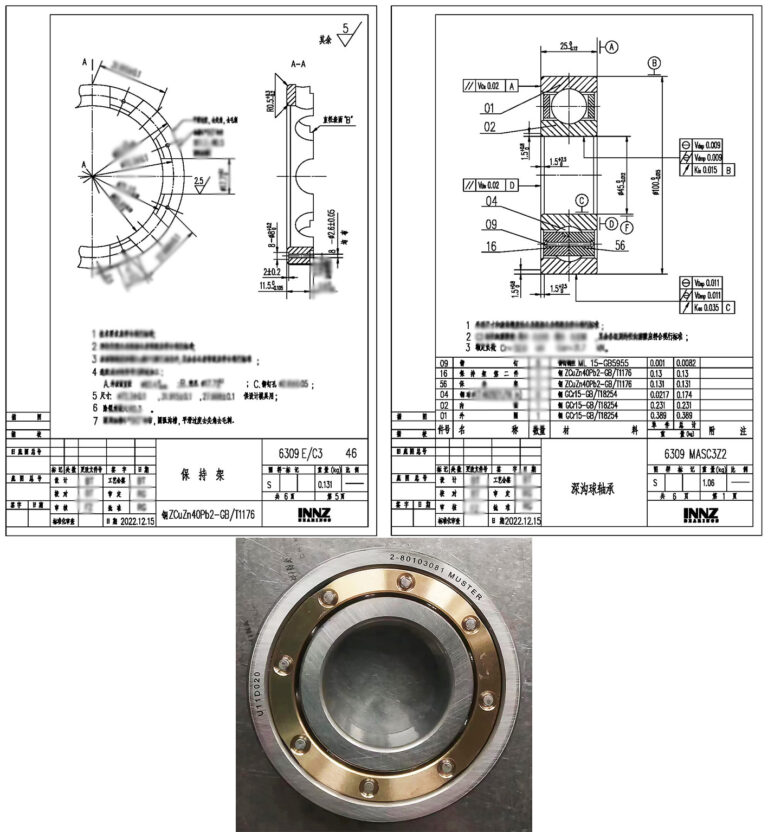

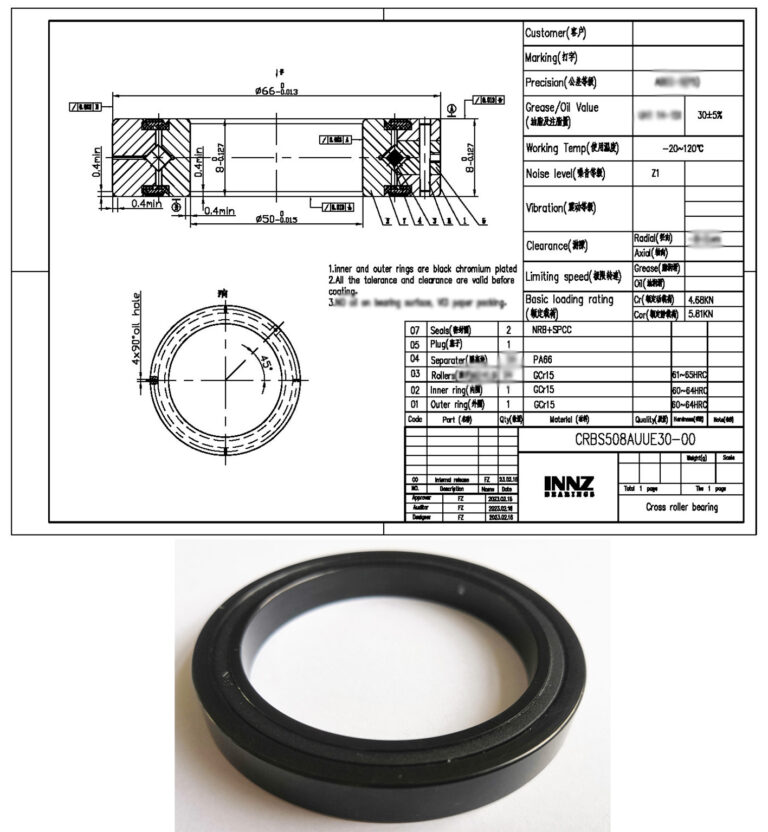

Engineering Cases we did